- Home

- Equipment

Refine by

Gea Bischoff Environmental Equipment & Supplies

7 equipment items found

Manufactured by:GEA Bischoff GmbH based inEssen, GERMANY

Bagfilters are the technology of choice in many cases when low dust content is needed for gas cleaning. Their ability to remove large Ioads on a non-selective basis has made them important for many ...

Manufactured by:GEA Bischoff GmbH based inEssen, GERMANY

For the removal of SO2 from industrial waste gases GEA Bischoff has available several different processes: Dry desulphurization by lime injection in the gas flow upstream bagfilters; Dry desulphurization in the circulized fluidized bed (CFB); Semi dry desulphurization by injection of lime milk in a spray absorber (SDA); Wet desulphurization in counter current scrubber with limestone (CaCO3) or ...

Manufactured by:GEA Bischoff GmbH based inEssen, GERMANY

For the denitrification of waste gases from glass furnaces or fluid catalytic crackers (FCC) plants GEA Bischoff offers the SCR DeNOx process. Selective catalytic reduction (SCR) is considered the most efficient commercially proven method of removing nitrogen oxides (NOx) from off-gases. ...

Manufactured by:GEA Bischoff GmbH based inEssen, GERMANY

Polychlorinated dibenzodioxin and dibenzofuran (PCDD/F) occur in very small concentrations in the off gases of several industrial combustion processes in a temperature range of 200 to 400 °C. A typical dimension of the concentration of these substances within the off-gases is 2 to 4 n/gm³ TE*. This organic contamination is extremely toxic, is not decomposing in the nature and is ...

Manufactured by:GEA Bischoff GmbH based inEssen, GERMANY

Wet electrostatic precipitators (WESP) are used to remove particulates and aerosols from saturated gases. They are operating with high efficiencies and can reach very low clean gas loads below 1 mg/ Nm3. Usually WESPs are built downstream ...

Manufactured by:GEA Bischoff GmbH based inEssen, GERMANY

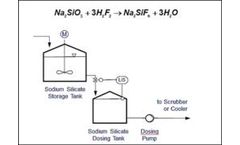

The removal of acid components (SO2, HCL, HF) from gases is important in case the cleaned gas is then treated in a sulphuric acid plant. SO3 is removed in wet electrostatic precipitators; HCL is washed out in scrubbers. For the removal of HF GEA Bischoff is using a sodium silicate dosing system. Sodium silicate as 10% water solution is dosed into the scrubber or cooling liquid circuit and quickly ...

Manufactured by:GEA Bischoff GmbH based inEssen, GERMANY

The off-gas of metallurgical processes such as copper smelters or zinc roasters are containing a high load of heavy metals, for instance lead (Pb), copper (Cu), chrome (Cr), nickel (Ni), cadmium (Cd), mercury (Hg). Most of these heavy metals are particulates, which are precipitated in the gas cleaning plant, mainly consisting of dry precipitator, scrubber and wet ...